Search This Supplers Products:Mold making Silicone rubberSilicone RubberLiquid Silicone rubberMolding Silicone RubberSilicone OilPad Silicone rubber

- Home

- About us

- Products

- RTV-2 silicone rubber for molds making

- Addition cure silicone rubber

- Life casting silicone rubber

- Liquid silicone rubber for insoles

- electronic potting silicone rubber

- injection moulding silicone rubber

- silicone foam

- Molding silicone rubber for tire molds

- Pad printing silicone rubber

- silicone rubber for textile coating& trademarks

- Other Silicone products

- Faqs

- News

- Certificate

- Contact us

shoe soles molding

- FOB Price

US $16.00200 - 40,000 kilogram

US $6.0040,001 - 999,999 kilogram

- group name

- RTV-2 silicone rubber for molds making

- Min Order

- 200 kilogram

- brand name

- Hong Ye silicone rubber

- model

- HY-520 HY-540 HY-570

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents

- update time

- Tue, 05 Nov 2013 12:17:04 GMT

Paramtents

Shaping Mode Silicone Mould

Product Material Rubber

Product Other

Packging & Delivery

-

Min Order200 kilogram

Briefing

B. Two-component silicone rubber with tin-catalyst

C. Cured under room temperature

Detailed

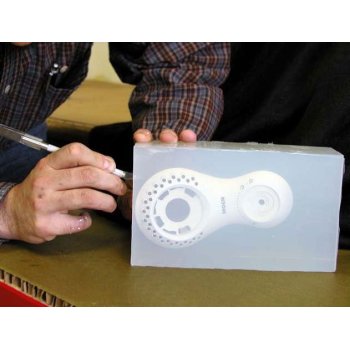

Shoe mold silicone rubber

A. mainly used for shoe soles mold making

B. Two-component silicone rubber with tin-catalyst

C. Cured under room temperature

D. low shrinkage

E. excellent fexibility & easy demould

Shoe mold silicone rubber applications

Shoe mold silicone rubber is mainly used for shoe molds, sand casting, sole sampling, plaster models, simple products, products with non-complex patterns, as well as product models with stable size and non-deformation.

Shoe Mold Silicone Rubber features:

- A. Two-component silicone rubber with tin-catalyst

- B. Cured under room temperature

- C. low shrinkage

- D. excellent fexibility & easy demould

Shoe Mold Silicone Rubber Standard Datasheet:

Model | Appearance | Viscosity (cps) | Hardness (A°) | Tensile Strength (Mpa) | Tear Strength (KN/m) | Elongation (%) | Mixing ratio (%) | Pot life(H) | Demould time(H) |

218 | White | ≤15000 | 18±2 | ≥1.3 | ≥5 | ≥300 | 2~3 | 0.5~2 | 2~4 |

Shoe Mold Silicone Rubber Using Instruction:

The component A of shoe Mold Silicone Rubberis white flowing liquid and the component B is the curing agent. For example, take silicone rubber of 100g and add 2% curing agent for mixing evenly. After the silicone rubber and the curing agent are completely mixed, put the silicon into a vacuum machine for deairing to remove the bubbles. After deaired, pouring the liquid silicone rubber into the product to be duplicated or into the mold frame.

Notes:

Shoe mold silicone rubber is used for pouring or brushing technique. That is to say, fix the product or sole model to be duplicated onto a plane plate, then enclose the plane frame with wooden plates to prevent the leakage of the silicon , mix the silicone rubber and the curing agent evenly according to the mixing ratio of 100 : 2 and pour them onto the sole model, then brush evenly with a wooden plate or a brush, and fill up the mold frame with gypsum after the silicone rubber is dried

Any questions of silicone rubber for moldmaking, please feel free to contact Kaimi:

TEL: 086-755-89212369

FAX: 086-755-89948030

MOBILE:086-18938867528

Website: www(dot)szrl(dot)net

E-MAIL: hyju(at)szrl(dot)net

skype:hyjiangying