Search This Supplers Products:Mold making Silicone rubberSilicone RubberLiquid Silicone rubberMolding Silicone RubberSilicone OilPad Silicone rubber

- Home

- About us

- Products

- RTV-2 silicone rubber for molds making

- Addition cure silicone rubber

- Life casting silicone rubber

- Liquid silicone rubber for insoles

- electronic potting silicone rubber

- injection moulding silicone rubber

- silicone foam

- Molding silicone rubber for tire molds

- Pad printing silicone rubber

- silicone rubber for textile coating& trademarks

- Other Silicone products

- Faqs

- News

- Certificate

- Contact us

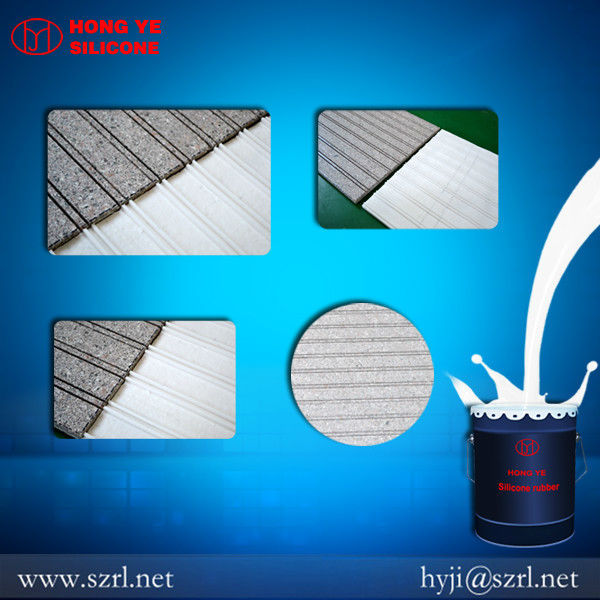

RTV-2 Silicone Rubber for Concrete Mold Making

- FOB Price

US $9.86200 - 40,000 kilogram

US $5.6140,001 - 999,999 kilogram

- group name

- RTV-2 silicone rubber for molds making

- Min Order

- 200 kilogram

- brand name

- Hong Ye silicone rubber

- model

- RTV 625

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents

- update time

- Tue, 05 Nov 2013 12:41:12 GMT

Paramtents

Available color white

Certifications RoHS.MSDS.SGS ISO9001:2000

Operation way pouring

Hardness 25 shore A

Curing time 30 - 40min

Mixing proportion of curing agent 100:4

Operating time 40-50min

Viscosity (MPas -25 0C) 10000

Tensile-strength(kgf /cm2 ) 80 ± 5

Packging & Delivery

-

Min Order200 kilogram

Briefing

High strength

High reproduce times

4% free catslyst

SGS

Detailed

RTV-2 silicone rubber for concrete mold making Key Performance Properties

High tear resistance

Long service life

Chemical resistance

Easy mould release

Compatible with most moulding materials

Excellent detail reproduction

Room temperature cure

Broad product range to suit individual needs

Datasheet for RTV-2 silicone rubber for concrete mold making

Model | 630 | GI-384GI-384 of Silicone, INC. |

Color | White | White |

Mixing ratio | 2~3% | 5% |

Pot life (mins, 25°C) | 30~50 | 60~120 |

Curing time (hrs, 25°C) | 4-5 | 16~18 |

Hardness ( shore A ) | 30±2 | 25~30 |

Tensile-strength (psi ) | 1000± 25 | 450 ± 25 |

Tear-strength (ppi) | 140± 25 | 125 ± 25 |

Viscosity(cps) | 27000 ± 3000 | 10,000-20,000 |

Shelf life (25°C) | 10~12months | 6 months |

OPERRATING INSTRUCTION of RTV-2 silicone rubber for concrete mold making

1. Stir part A and part B with right mixing ratio evenly. And get the mixture for vacuum-pumping. (If there is no vacuumizer, you can just pour the mixture slowly from the corner so that less bubbles caused)

2. Enclose the product (the original model) with four plastic plates or wooden plates.

3. Clean your products and brush a layer of release agent(detergent or soap water) on your product.

4. Pour the mixture with correct mixing ratio into the model frame.

After about 2-4 hours, when the silicone cured, get out the original model, and there you get a finished addition cured silicone mold .

Any questions of Silicone Rubber, please feel free to contact Miss Leah:

TEL: 086-755-89212382

FAX: 086-755-89948030

MOBILE: 086-189 3886 7561

Website: www(dot)szrl(dot)net

E-MAIL: hyji(at)szrl(dot)net

Skype: leahchou1214

QQ: 189 3886 7561