Search This Supplers Products:Mold making Silicone rubberSilicone RubberLiquid Silicone rubberMolding Silicone RubberSilicone OilPad Silicone rubber

- Home

- About us

- Products

- RTV-2 silicone rubber for molds making

- Addition cure silicone rubber

- Life casting silicone rubber

- Liquid silicone rubber for insoles

- electronic potting silicone rubber

- injection moulding silicone rubber

- silicone foam

- Molding silicone rubber for tire molds

- Pad printing silicone rubber

- silicone rubber for textile coating& trademarks

- Other Silicone products

- Faqs

- News

- Certificate

- Contact us

Injection molding silicone rubber for jewelry casting,liquid silicone rubber

- FOB Price

US $11.98200 - 40,000 kilogram

US $9.8840,001 - 999,999 kilogram

- group name

- silicone rubber for textile coating& trademarks

- Min Order

- 200 kilogram

- brand name

- Hong Ye silicone rubber

- model

- HY-2130

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents

- update time

- Fri, 08 Nov 2013 21:15:07 GMT

Paramtents

Color high translucent

high translucent 1:1

Certification SGS,MSDS,RoHS

Material 100% silicone

Application Injection molding silicone rubber for jewelry casting

Classification Chemical Auxiliary Agent

Supply ability 8 ton per day

Sample Free

Hs code 39100000

Payment Term L/C T/T

Packging & Delivery

-

Min Order200 kilogram

Briefing

Favorable tension;

No deformation;

High temperature resistance.

Detailed

Injection molding silicone rubber for jewelry casting Application:

1. Silicone Medical products

2. Silicone Food grade products

3. Silicone Baby product

4. Silicone Household product

5. Crafts and Gift product

6. Silicone Industries in all areas

Injection molding silicone rubber for jewelry casting Feature:

Injection molding silicone rubber for jewelry casting is a two-component liquid silicone rubber for injection molding processes. HY-2130 shows a higher productivity, less yellowing and low volatile contents. HY-2130 would be possible to increase productivity by reduce injection time and total cycle time. Also, it is easier to inject into the cavity of the mold which is more complicated designed. In addition, higher transparency and less volatile content make it most suitable for consumer products.

Injection molding silicone rubber for jewelry casting Advantage:

- Relative low viscosity , not only can be pumped to mix, but also can be formed the continuous automation during the process of measurement, mixing, injection molding. as well as formed products with different complex shapes.

- Curing speed can be finished within 20~30mins and the molding cycle time is less than 1min, which is good for saving costs, efforts and be high efficiency.

- with low molding pressure, accurate measurement, high precision molds, products can be perfectly formed with no flash or defects, which helps to save cost on raw materials and post-working process.

- The performance of finished products can be compared favorably to HTV silicone rubber, while the labor costs can be saved by half.

- The vulcanizing system of this product is the same as other addition-cured silicone rubber, but there won’t be peroxide decomposition products which generated by HTV silicone cured. It is with high transparency, high tear strength, good elasticity, good weather-ability, and with resistance of high temperature, aging, as well as excellent resistance to yellowing.

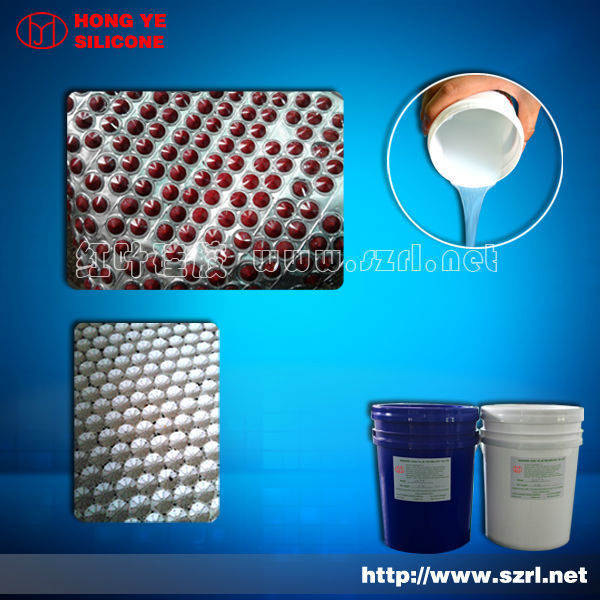

Injection molding silicone rubber for jewelry casting Picture Show:

Injection molding silicone rubber for jewelry casting Typical Physical Properties:

Product | HY-2130 |

Appearance | Translucent |

Hardness(shore A) | 25±2 |

Mix ratio(A:B) | 10:1 |

Viscocity Part A(mPa.s) | 60000±2000 |

Viscocity Part B(mPa.s) | 35000±500 |

Tensile strength (kgf/cm2) | 32±5 |

Tear-strength (kN/m) | 18±2 |

Elongation(%) | 500±50 |

Pot life/working time (mins) | 30-40 |

Curing time/setting time (hrs) | 3-4hrs(25°C) 110-20mins(60°C) |

Shrinkage rate (%) | 0.1 |

Injection molding silicone rubber for jewelry casting Processing Recommendations:

Ready-to-use mixtures (of the components A and B) are fed directly to the injectionmoulding machine from the original containers by means of a metering and mixing unit. The mixture, consisting of the two components in the ratio 10:1, is injected into the heated mould. Because of low viscosity, the injection daospeed and injection pressure need to be carefully adjusted so that the injection time can be decreased. At mould temperatures of 170 - 230°C, the addition -crosslinking silicone rubber vulcanises free of dissociation products within a few seconds. Excellent flowability and easy demoulding permit fully automated production of large numbers of articles in shorter total cycle times.

Injection molding silicone rubber for jewelry casting Shelf life:

8-10 months when stored under 24°C in original unopened packages.

Injection molding silicone rubber for jewelry casting Package:

Packed in 20kg/pail + 20kg/pail and 200kg/pail + 200kg/pail.

Injection molding silicone rubber for jewelry casting Certification:

ISO9001: HK05/01358

SGS:GZ0606100461/CHEM

RoHS:BTRS091718751

Patent:ZL200520001597.8

Need any help on silicone rubber, please feel free to contact Ms Kitty:

Tel:86-755-89948294

Mob:86-18938867593

E-mail: hysh(at)szrl(dot)net

Skype:kity-467707861

You can also send me e-mail by scanning 2 Dimensional Bar Code below:

Injection molding silicone rubber for jewelry casting Making equirement: