Search This Supplers Products:Mold making Silicone rubberSilicone RubberLiquid Silicone rubberMolding Silicone RubberSilicone OilPad Silicone rubber

- Home

- About us

- Products

- RTV-2 silicone rubber for molds making

- Addition cure silicone rubber

- Life casting silicone rubber

- Liquid silicone rubber for insoles

- electronic potting silicone rubber

- injection moulding silicone rubber

- silicone foam

- Molding silicone rubber for tire molds

- Pad printing silicone rubber

- silicone rubber for textile coating& trademarks

- Other Silicone products

- Faqs

- News

- Certificate

- Contact us

How to make a silicone printing pad ?

- FOB Price

US $15.60200 - 40,000 kilogram

US $9.8040,001 - 999,999 kilogram

- group name

- Pad printing silicone rubber

- Min Order

- 200 kilogram

- brand name

- Hong Ye silicone rubber

- model

- hy-912 silicone

- Nearest port for product export

- Shenzhen, Guangzhou, Xiamen, Shanghai

- Delivery clauses under the trade mode

- FOB, CFR, CIF

- Acceptable payment methods

- T/T, L/C, Westem Union

- Export mode

- Export through agents

- update time

- Sat, 09 Nov 2013 12:54:20 GMT

Paramtents

color any

Certifications ISO9001:2000

Packging & Delivery

-

Min Order200 kilogram

Briefing

2.good quality

3.good resilience

4.without any impurity

Detailed

Usage of pad printing silicon

Pad printing silicon is mainly applicable to the printing of irregular patterns on plastics toys, electroplating products, electronic toys, trademarks, artwork gifts, and stationery, etc.

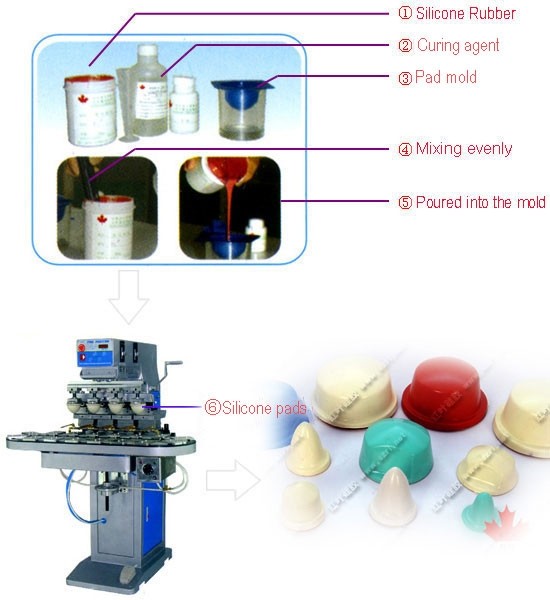

How to make a silicone pad?

1) At first, prepare all the tools like the pad mold, a cup for mixing, and a glass stick. Clean the pad mould with detergent, and dry the pad mould with an air-gun or cloth, then brush a lay of mold release agent.

2) For second step, adjust the ratio between the silicon rubber and silicon oil according the customer’s requirement. If customers want to print large pattern, soft silicon pad need and silicon oil need to add, otherwise, hard silicone pad need, less silicone oil to add or none.

3)vacuum pumping

Without exception, this step takes less than 10 minutes. Otherwise, it will cause cross linking reaction, and no more further steps will be available.

For get further information about our silicone product, PLS contact with Miss Rose

TEL: 0086-75589948294

Mobile:086-18938867525

FAX: 086-755-89948030